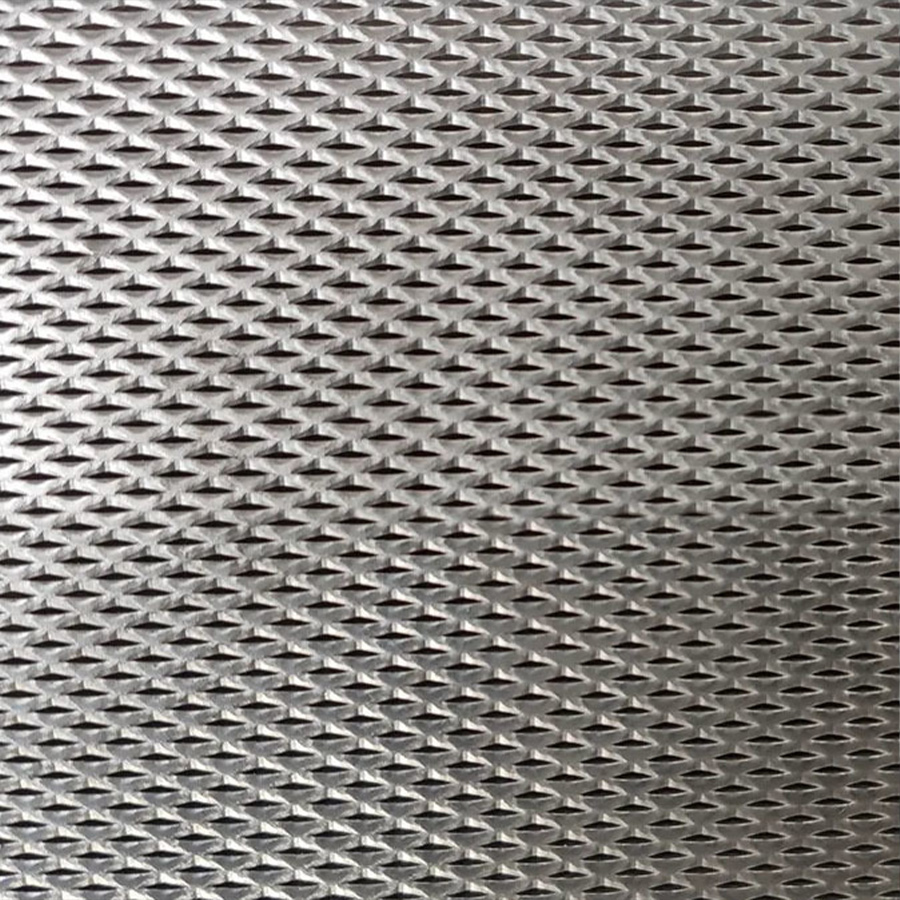

Hexagonal mesh

Features of hexagonal mesh

Features

Features of hexagonal mesh:

1、Versatility: Ideal for various applications, from poultry enclosures to garden fencing.

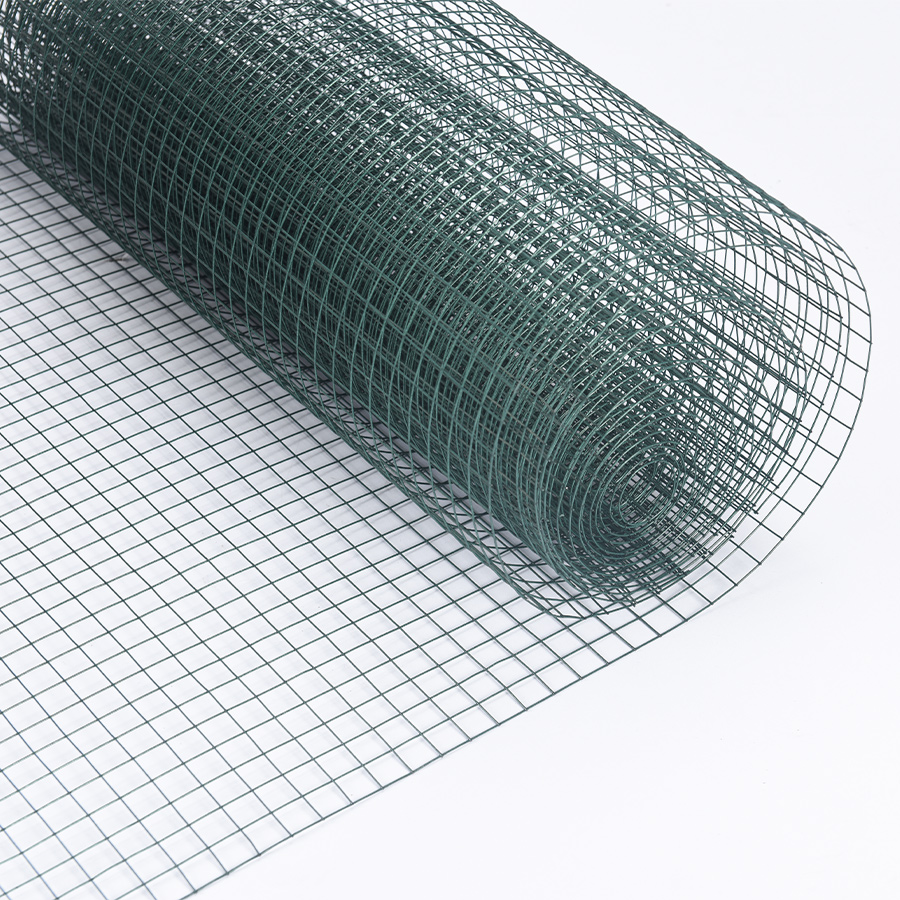

2、Durability: Galvanized or PVC-coated options enhance corrosion resistance and lifespan.

3、Lightweight: Easy handling and installation, reducing labor requirements.

4、Ventilation: Allows proper airflow, crucial for poultry health.

5、Security: Protects chickens from predators while providing visibility

6、Cost-effective: Affordable for agricultural and domestic use.

7、Flexibility: Adapts to uneven terrain and can be shaped to fit different spaces.

8、Low Maintenance: Simple cleaning and repair, ensuring long-term use.

9、Environmentally Friendly: Recyclable and made from non-toxic materials.

10、Reliable Containment: Prevents escape, maintaining a secure chicken enclosure.

Benefits

Benefits of hexagonal mesh:

1、Predator Protection: Shields chickens from threats like foxes, raccoons, and birds of prey.

2、Ventilation: Ensures proper airflow, preventing overheating and humidity buildup in coops.

3、Disease Control: Reduces the risk of disease transmission by keeping pests out.

4、Easy Maintenance: Simple to clean and repair, minimizing upkeep efforts.

5、Versatility: Useful for various applications, including garden fencing and animal enclosures.

6、Cost-Efficiency: An affordable option for safeguarding poultry and other animals.

7、Visibility: Allows monitoring of chickens and prevents them from feeling isolated.

8、Longevity: Galvanized or PVC-coated options enhance durability and extend the mesh's lifespan.

9、Environmentally Friendly: Made from recyclable and non-toxic materials.

10、Peace of Mind: Provides peace of mind knowing your chickens are safe and secure.

Advantages

Advantages of hexagonal mesh:

hexagonal mesh offers numerous benefits for poultry and small animal management:

1、Predator Protection: It effectively shields chickens from potential threats such as foxes, raccoons, and birds of prey, ensuring their safety.

2、Ventilation: The mesh design promotes proper airflow within coops, preventing overheating and moisture buildup, which is vital for the health of your animals.

3、Disease Prevention: By keeping pests out, chicken mesh reduces the risk of disease transmission, contributing to the overall well-being of your flock.

4、Low Maintenance: hexagonalmeshis easy to clean and repair, reducing both the time and cost associated with upkeep.

5、Versatility: Its flexibility allows for various applications, including garden fencing and creating enclosures for other small animals.

6、Cost-Effective: It is an affordable option for protecting poultry and livestock, making it accessible for many farmers and enthusiasts.

7、Visibility: hexagonalmeshprovides a clear view of your chickens while ensuring they don't feel isolated or confined.

8、Longevity: Options like galvanized or PVC-coated mesh enhance durability, prolonging the mesh's lifespan.

9、Eco-Friendly: Made from recyclable and non-toxic materials, it aligns with sustainable practices.

10、Peace of Mind: Ultimately, hexagonalmeshoffers peace of mind, knowing that your animals are secure and well-protected.

Spec-Material

Materials of hexagonal mesh:

1、Galvanized Steel: This is a common material, coated with a layer of zinc for corrosion resistance.

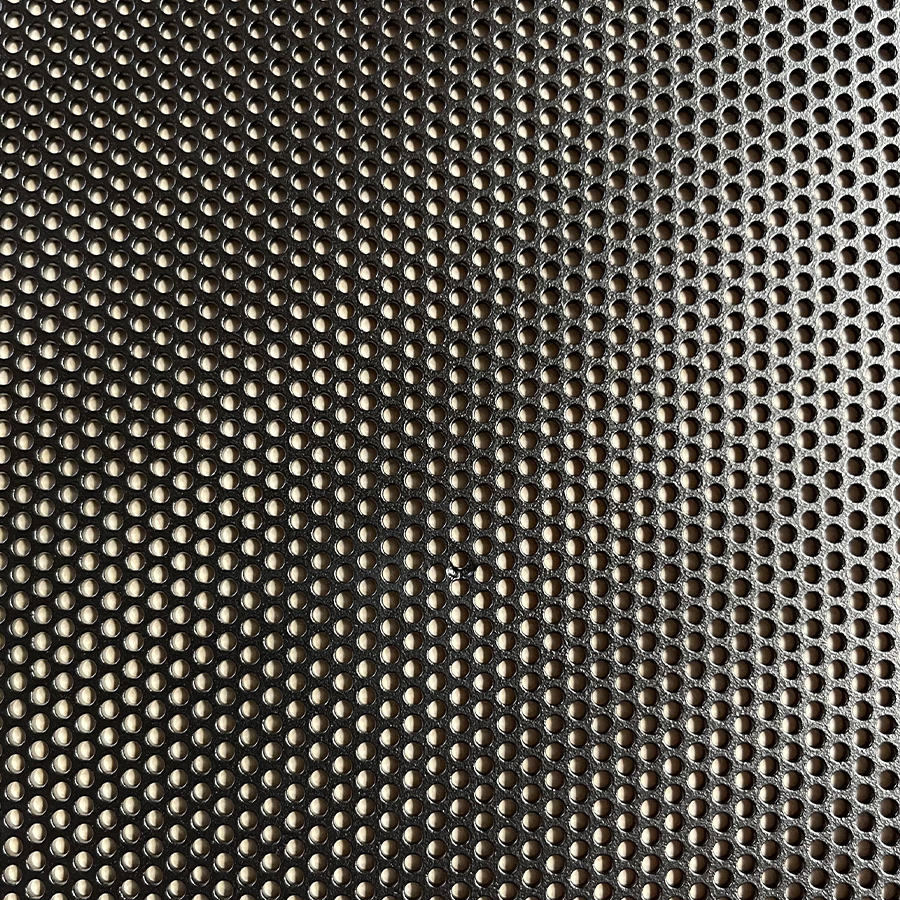

2、PVC-Coated Steel: Galvanized steel mesh can also be further coated with PVC for added protection and durability.

3、Stainless Steel: Known for its rust-resistant properties, stainless steel mesh is long-lasting.

4、Aluminum: Lightweight and resistant to corrosion, aluminum mesh is suitable for less demanding applications.

5、Polypropylene: A synthetic material that is lightweight and resistant to chemicals and moisture, often used in poultry netting.

6、Hexagonal Wire Netting: Traditional chicken mesh is often made from galvanized or PVC-coated steel wire, formed into a hexagonal pattern.

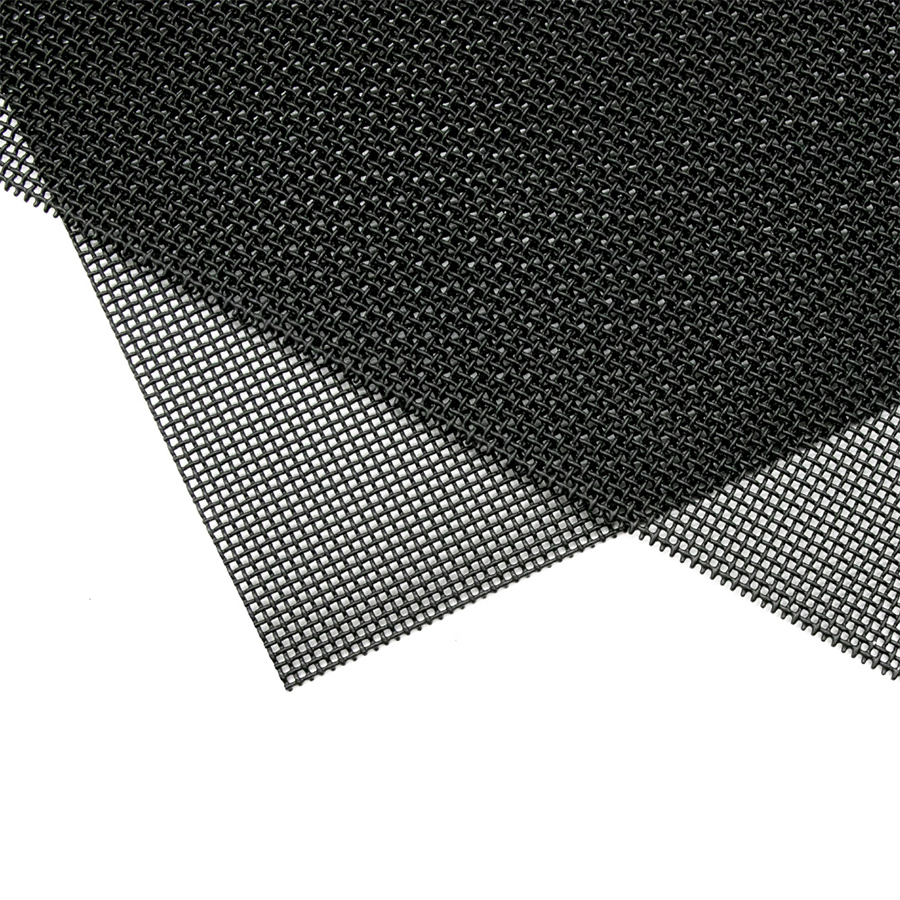

7、Welded Wire Mesh: This type of mesh is made from welded steel wires, offering strength and durability.

8、Plastic Mesh: Lightweight and affordable, plastic mesh is suitable for temporary enclosures and less harsh environments.

The choice of material depends on factors such as budget, intended use, and the level of protection required for your chickens or other animals.

Spec-Chart or Graphic

|

Opening size |

Wire Gauge |

Roll Width |

Roll length |

|||

|

Inch |

mm |

Tolerance |

BWG |

mm |

Meter |

Meter |

|

3/8” |

10 |

±0.5 |

BWG27-23 |

0.41-0.64 |

0.1-2m |

10/15/30/50m |

|

1/2” |

12.5 |

±1 |

BWG27-22 |

0.41-0.71 |

0.1-2m |

10/15/30/50m |

|

5/8” |

16 |

±1 |

BWG27-22 |

0.41-0.71 |

0.1-2m |

10/15/30/50m |

|

3/4” |

19 |

±1 |

BWG26-20 |

0.46-0.89 |

0.1-2m |

10/15/30/50m |

|

1” |

25 |

±1.5 |

BWG25-29 |

0.51-1.07 |

0.1-2m |

10/15/30/50m |

|

11/4” |

31 |

±2 |

BWG24-18 |

0.56-1.24 |

0.2-2m |

10/15/30/50m |

|

11/2” |

40 |

±3 |

BWG23-16 |

0.64-1.65 |

0.2-2m |

10/15/30/50m |

|

2” |

51 |

±3.5 |

BWG22-14 |

0.71-2.11 |

0.2-2m |

10/15/30/50m |

|

3” |

76 |

±4 |

BWG21-14 |

0.81-2.11 |

0.3-2m |

10/15/30/50m |

|

4” |

100 |

±4 |

BWG20-12 |

0.89-2.8 |

0.5-2m |

10/15/30/50m |

|

Note:Special size and specifications can be made according to customers requires |

||||||

Spec-Standards

Standards for hexagonal mesh can vary depending on the intended application and industry.

1、ASTM Standards: The American Society for Testing and Materials (ASTM) provides various standards for wire mesh, including hexagonal mesh, covering materials, dimensions, and testing methods.

2、ISO Standards: The International Organization for Standardization (ISO) offers international standards for wire mesh, ensuring consistency in quality and specifications worldwide.

3、Wire Gauge Standards: Different countries have wire gauge standards (e.g., SWG in the UK, AWG in the US) that specify wire thickness for hexagonal mesh.

4、Mesh Size: Standards may define the mesh size in terms of the number of openings per unit length or area, ensuring uniformity.

5、Coating Standards: When hexagonal mesh is coated (e.g., galvanized or PVC-coated), standards may specify coating thickness and adherence requirements.

6、Industry-Specific Standards: Certain industries, such as agriculture or construction, may have specific standards for hexagonal mesh used in their applications.

It's essential to consult the relevant standards and specifications based on your specific needs and location to ensure compliance and quality in your hexagonal mesh products.

Applications of hexagonal mesh include:

1、Poultry Fencing: Hexagonal mesh is commonly used to create enclosures for chickens and other poultry, providing protection from predators while allowing ventilation.

2、Garden Protection: It serves as garden fencing, keeping out small animals like rabbits and rodents that may damage plants.

3、Erosion Control: Hexagonal mesh can stabilize soil on slopes and prevent erosion.

4、Aquaculture: Used in fish farming to create cages and enclosures for aquatic species.

5、Gabion Boxes: Hexagonal mesh is formed into boxes and filled with stones to create retaining walls and erosion control structures.

6、Construction Reinforcement: It reinforces plaster and concrete, providing strength and stability in construction.

7、Decorative and Arts: Utilized in art installations, sculptures, and architectural designs for its aesthetic appeal.

8、Mining and Screening: Used as screens for sifting and sorting materials in mining and industrial processes.

9、Rodent Exclusion: Hexagonal mesh can keep rodents out of homes and structures when used in vents or openings.

10、Security: In some cases, it is employed for security purposes, such as fencing for secure facilities.

|

|

The installation of hexagonal mesh depends on the specific application, but here is a general overview of how it can be installed:

1、Prepare the Area: Clear the area where you intend to install the hexagonal mesh. Ensure that the ground is level and free from any obstructions.

2、Measure and Cut: Measure the required length of hexagonal mesh using a tape measure and cut it to size using wire cutters or shears.

3、Secure Posts: If you're using hexagonal mesh for fencing or as a structure, install wooden or metal posts at regular intervals around the perimeter of the area. These posts will support the mesh.

4、Attach the Mesh: Start at one end and attach the hexagonal mesh to the posts using wire ties, staples, or fencing clips. Ensure it is stretched tight to prevent sagging.

5、Join Sections: If you have multiple sections of hexagonal mesh, overlap them by several inches and secure them together using wire ties or clips.

6、Bury the Bottom: If you're using the mesh to prevent digging animals from burrowing underneath, bury the bottom edge of the mesh a few inches underground and secure it with stakes or rocks.

7、Tension and Adjust: Periodically check the tension of the mesh and adjust it as needed to maintain a tight and secure installation.

8、Finishing Touches: Trim any excess mesh if necessary and make sure all connections are secure.

9、Optional Coating: If you're using galvanized hexagonal mesh, it may already have a protective coating. If not, consider adding a coating for additional durability and corrosion resistance.

10、Final Inspection: Walk around the installation to ensure there are no loose or sharp edges that could pose a safety hazard.

Remember that the specific installation process may vary depending on the application and the type of hexagonal mesh you are using. Always follow manufacturer guidelines and safety precautions when working with mesh materials.

Hexagonal mesh is typically available in various packaging options to suit different needs:

1、Rolls: Hexagonal mesh is often packaged in rolls, making it easy to transport and unroll for installation. Roll lengths can vary from a few feet to several hundred feet, depending on the supplier and application.

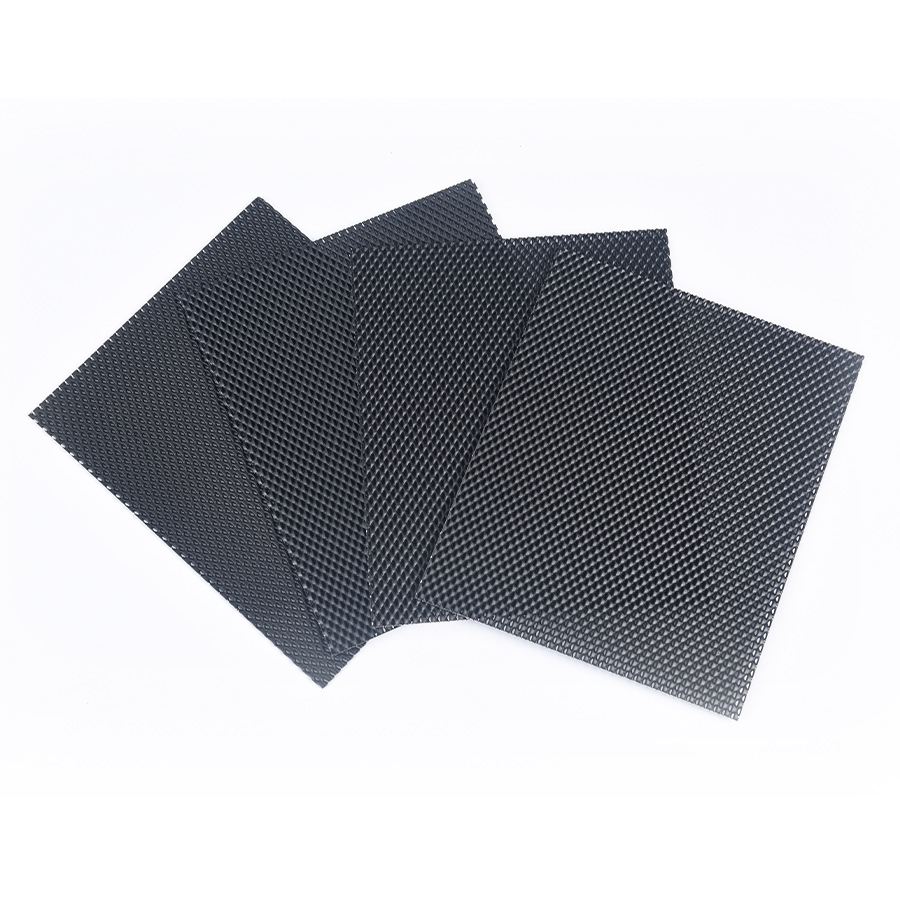

2、Sheets or Panels: Some hexagonal mesh may be sold in pre-cut sheets or panels, which are convenient for smaller-scale projects or when precise dimensions are required.

3、Bulk/Loose: In industrial or large-scale construction applications, hexagonal mesh may be sold in bulk or loose form, typically in large quantities.

4、Custom Cuts: Some suppliers offer custom cutting services, allowing customers to specify the dimensions they need for their project.

5、Bags: For small or DIY projects, hexagonal mesh may come in bags or smaller packages, suitable for garden or craft applications.

6、Pallets: Large orders of hexagonal mesh may be palletized for easy shipping and handling.

The choice of packaging depends on the quantity required, the size of the project, and the preferences of the customer.