Galvanized Iron Wire

Galvanized iron wire is relatively easy to handle and work with, whether you're using it for crafting or industrial purposes. It can be bent, twisted, and cut as needed.

Galvanized iron wire is a type of steel wire that has been coated with a layer of zinc to protect it from corrosion.

Low carbon steel: SAE1006, SAE1008, SAE1010, Q195, Q235, C45, C50, C55, C60, C65.

Elongation: 15%.

Tensile strength: 300N-680N/mm2

Zinc coating: 30g-350g/m2.

Standard:ASTM A123/A123M,A641/A641M,BS 302

———— Edith

Features

1、Ease of Handling: Galvanized iron wire is relatively easy to handle and work with, whether you're using it for crafting or industrial purposes. It can be bent, twisted, and cut as needed.

2、Cost-Effective: While it may be slightly more expensive than untreated iron wire, the extended lifespan and reduced maintenance costs make galvanized iron wire cost-effective in the long run.

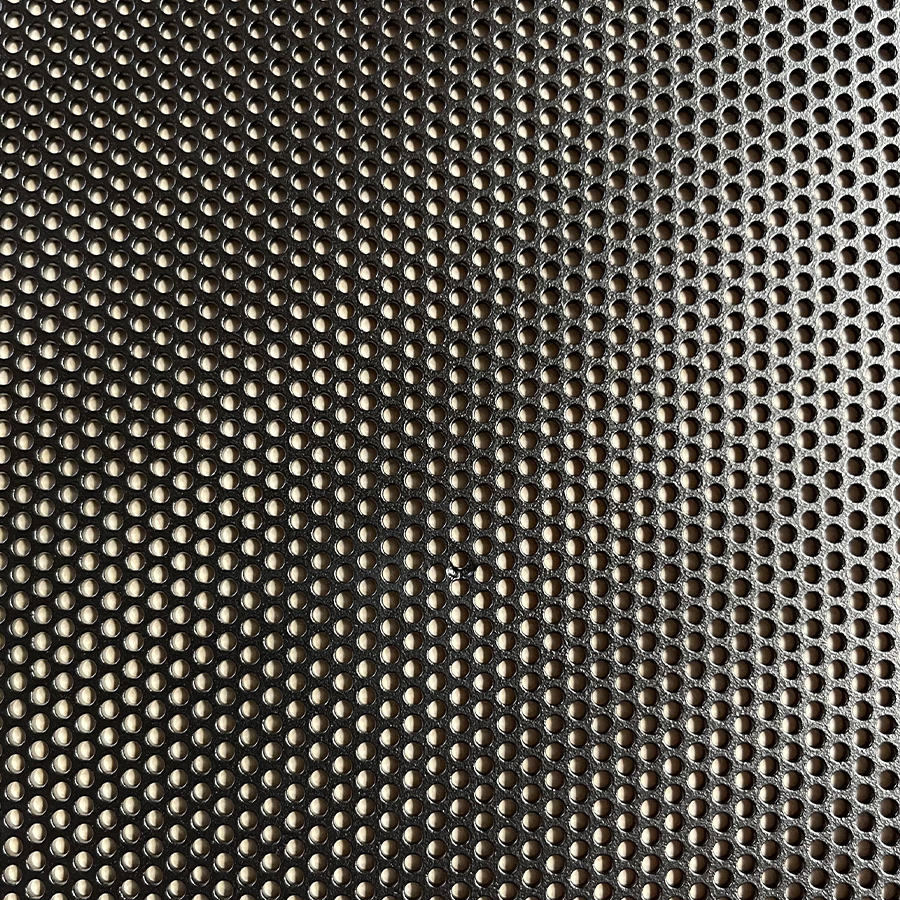

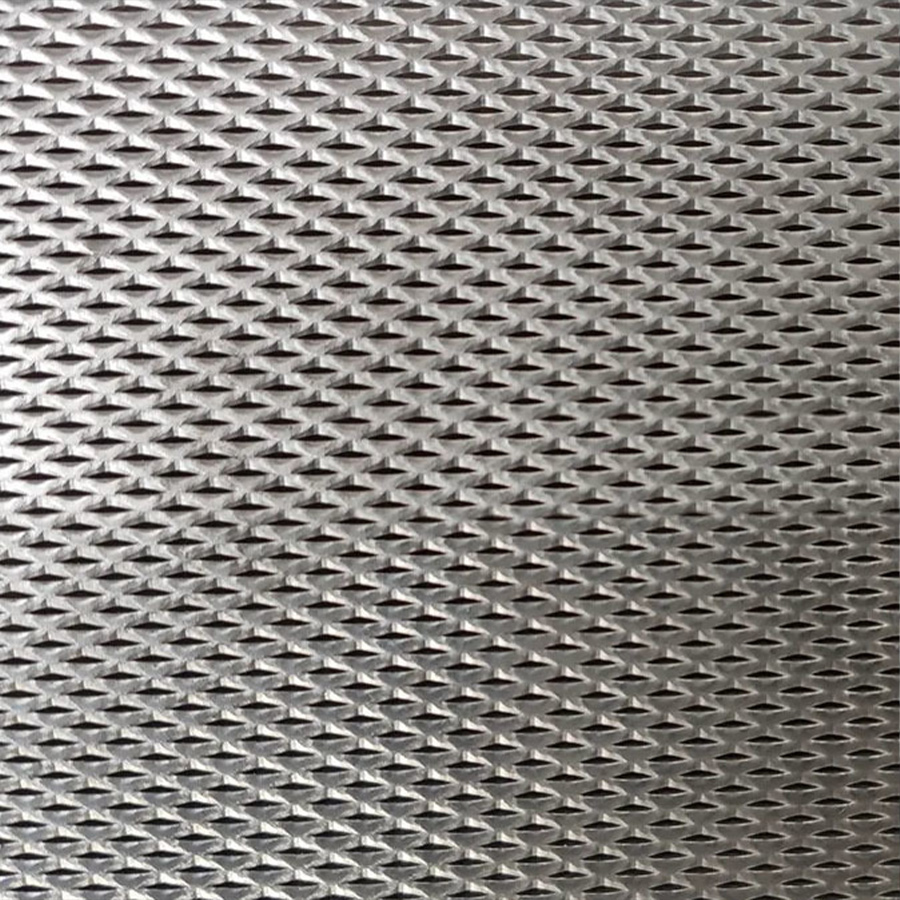

3、Aesthetic Appeal: In addition to its functional benefits, galvanized iron wire has a distinct silver-gray appearance that some people find visually appealing. It can be used in decorative applications as well.

4、Environmental Benefits: Galvanization is considered an environmentally friendly process because it extends the life of iron products, reducing the need for frequent replacements and conserving resources.

5、Resistance to UV Radiation: Galvanized wire is also resistant to UV radiation from the sun, which can further enhance its longevity when used outdoors.

6、Rust Prevention: The zinc coating effectively prevents the formation of rust and rust-related issues, ensuring that the wire maintains its integrity over time.

Benefits

1、Corrosion Resistance: Galvanized iron wire is highly resistant to corrosion due to the protective zinc coating. This makes it ideal for outdoor and marine applications where exposure to moisture and harsh weather conditions is a concern.

2、Durability: The zinc coating provides an extra layer of protection, increasing the wire's lifespan and making it more durable. It can withstand wear and tear better than untreated iron wire.

3、Strength: Galvanized iron wire is known for its strength and tensile properties. It can be used in various heavy-duty applications, such as fencing, construction, and agriculture.

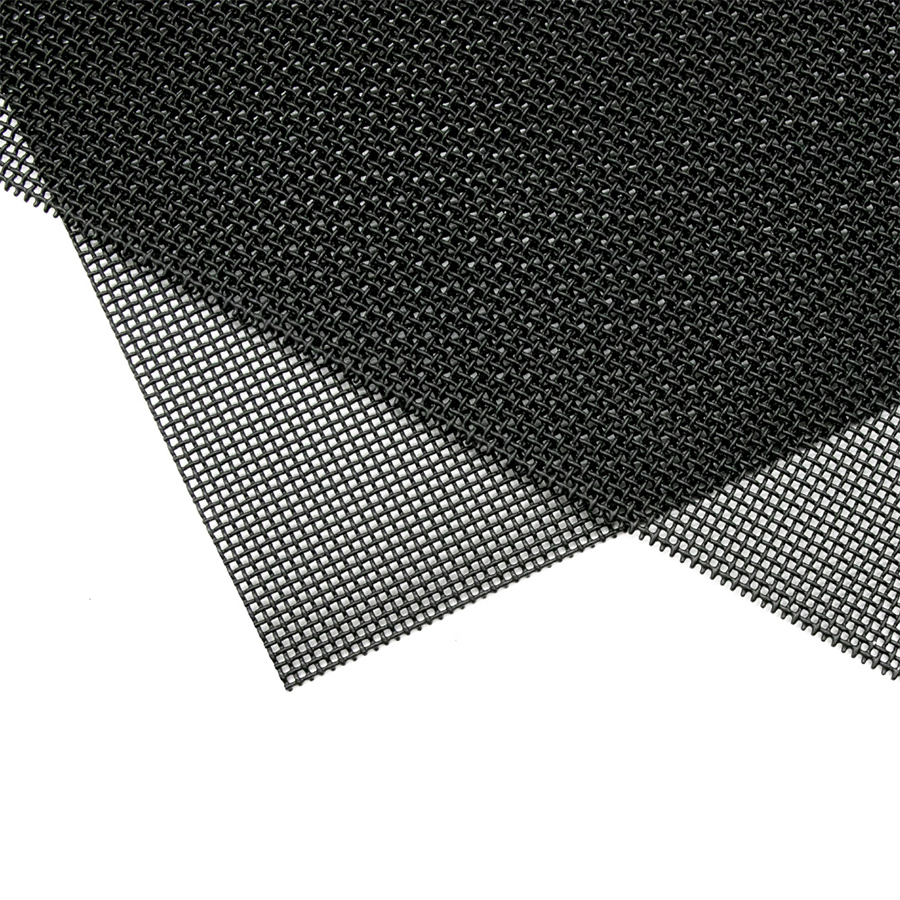

4、Versatility: It comes in various thicknesses and forms, making it suitable for a wide range of applications. Different gauges and styles of galvanized wire are available to meet specific needs.

Galvanized Iron Wire Specification:

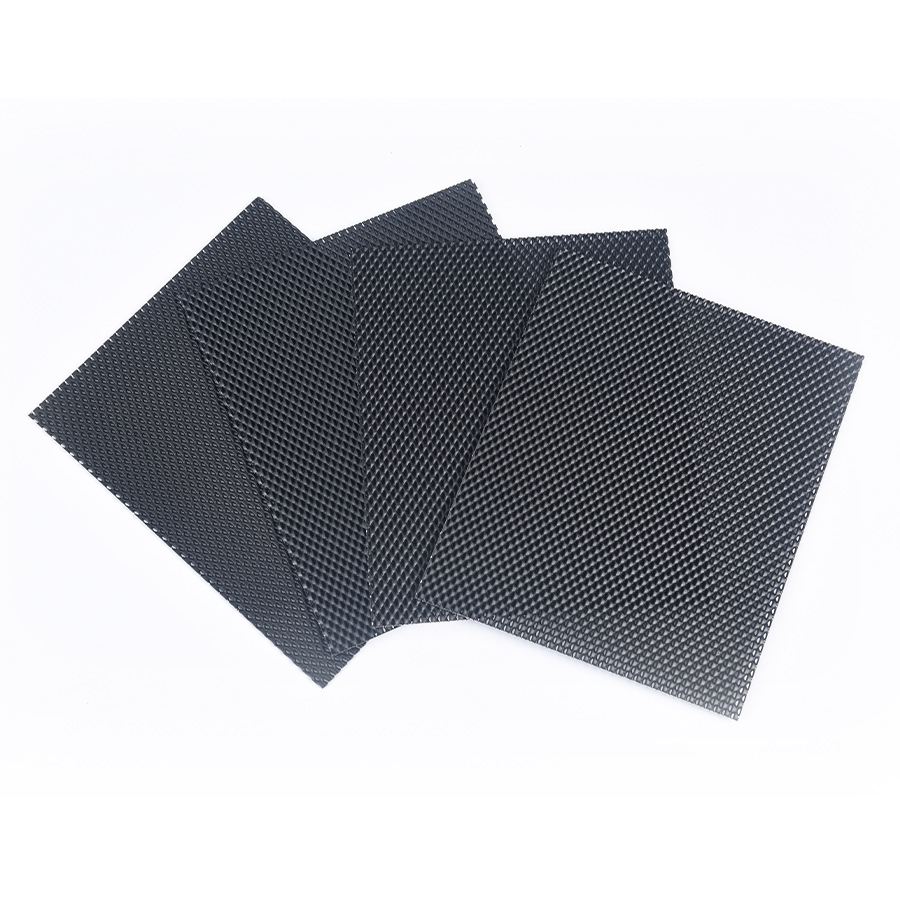

1、 Binding Materials

Because galvanized steel wire is strong and durable. It is often used as binding or baling or earthing materials on construction sites. Due to its weather resistance, it is very popular among builders. You can also find GI wires used to make gabions.

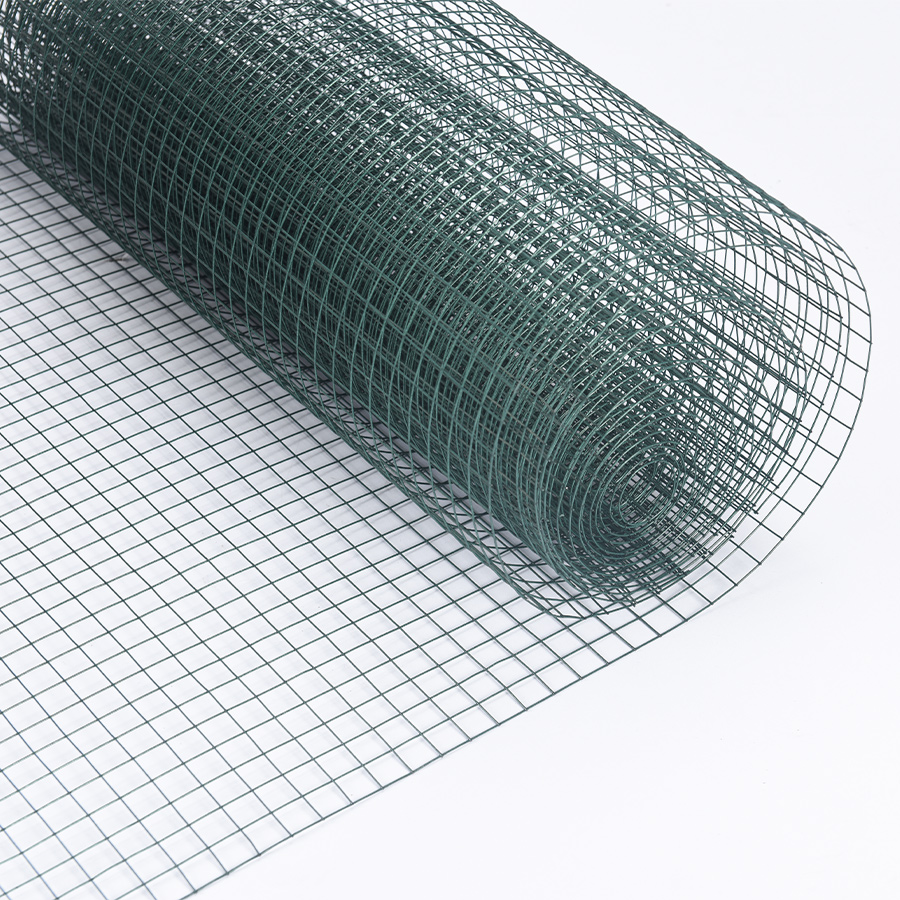

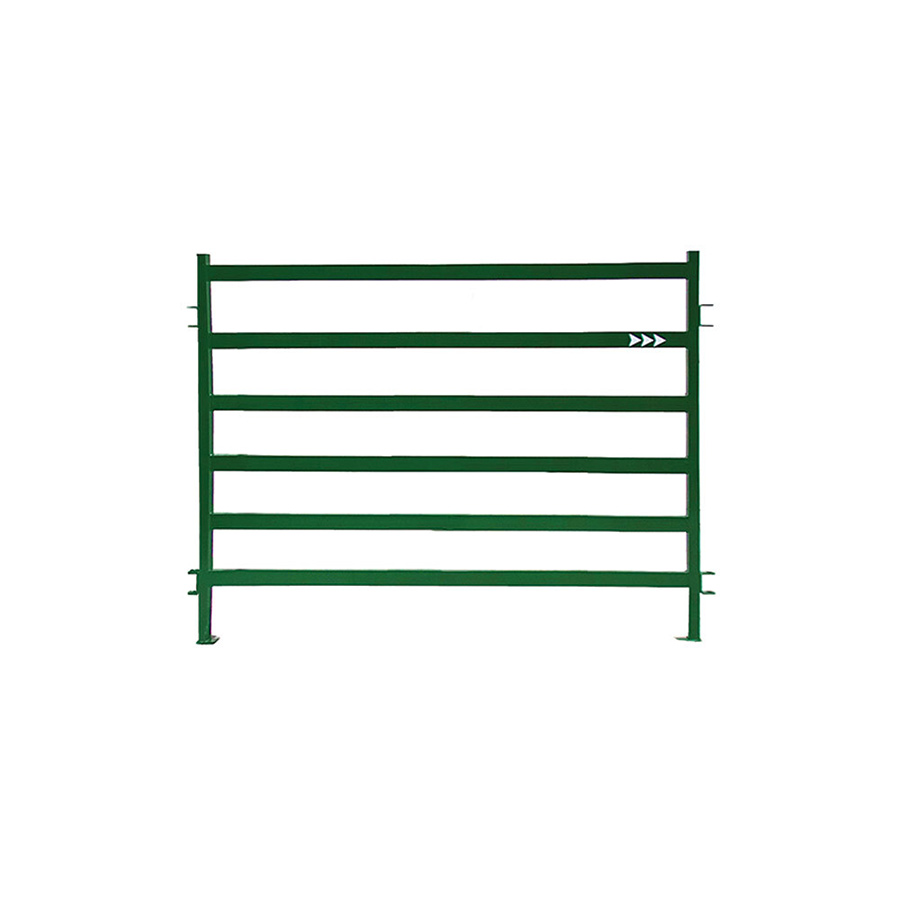

2、 Protective Fencing

Since galvanized steel wire is strong, it is widely used to make fencing or enclosure around your home or property from thieves or animals. Besides that, galvanized steel wire is corrosion resistant which makes it suitable for outdoor uses. You can also find GI wire fencing around schools, sports fields, etc. A GI wire fence will be an easy and useful way to keep your home safe and secure.

3、Making Handicrafts

The galvanizing process gives steel wire a bright and glossy surface. It can be made into household handicrafts such as bookshelves, vase holders, storage baskets, etc.

4、Agricultural Uses

GI wire is also widely used in orchards for supporting the growth of grapes or tomatoes and other vegetable farming. Due to the zinc coating, it can withstand the corrosion of pesticides and other chemicals.

5、Other Daily Uses

Galvanized wiring is also often used in packaging, animal cages, hanging pictures or painting, etc.

|

|

|

Production

Wire Rods — Pickling (annealing – rust removing – acid washing) — Wire Drawing Process — Galvanizing Process — Stranding

The first step is the pickling process, including annealing, rust removing and acid washing, which aims to remove the impurities on the surface of wire rods. Then it will go through the drawing machine, steel wires will be formed into the desired size. Then the wire will be galvanized by dipping into zinc solution or electroplating. This is the main difference between hot-dipped galvanized and electro galvanized wires. After galvanizing, the GI wires will be rolled into coils for sale.

Coils: Galvanized iron wire is often wound into coils, which can vary in size and weight. Coils are a convenient option for handling and transportation. They are commonly used in construction and fencing applications.

Spools: For more precise and controlled dispensing of the wire, it can be wound onto plastic or wooden spools. This is commonly seen in smaller gauge wires and for applications like arts and crafts.

Drums: In industrial or large-scale applications, galvanized iron wire may be packaged on larger drums or reels. These drums can hold significant lengths of wire and are suitable for heavy-duty usage.

Pallets: When large quantities of galvanized iron wire are required, it may be bundled and packaged on pallets for easy storage and transportation. This is common for industrial or construction supplies.

Bundles: Smaller lengths of galvanized wire may be bundled together and tied with wire or plastic strapping. This is a simple and cost-effective way to package shorter pieces of wire.

Boxes or Cartons: Galvanized iron wire can also be packaged in boxes or cartons, especially for retail or smaller consumer-oriented sales.

Hanks: In some cases, galvanized wire is packaged in hanks, which are loops or coils that are secured at one end. This is commonly used in agricultural and rural settings.