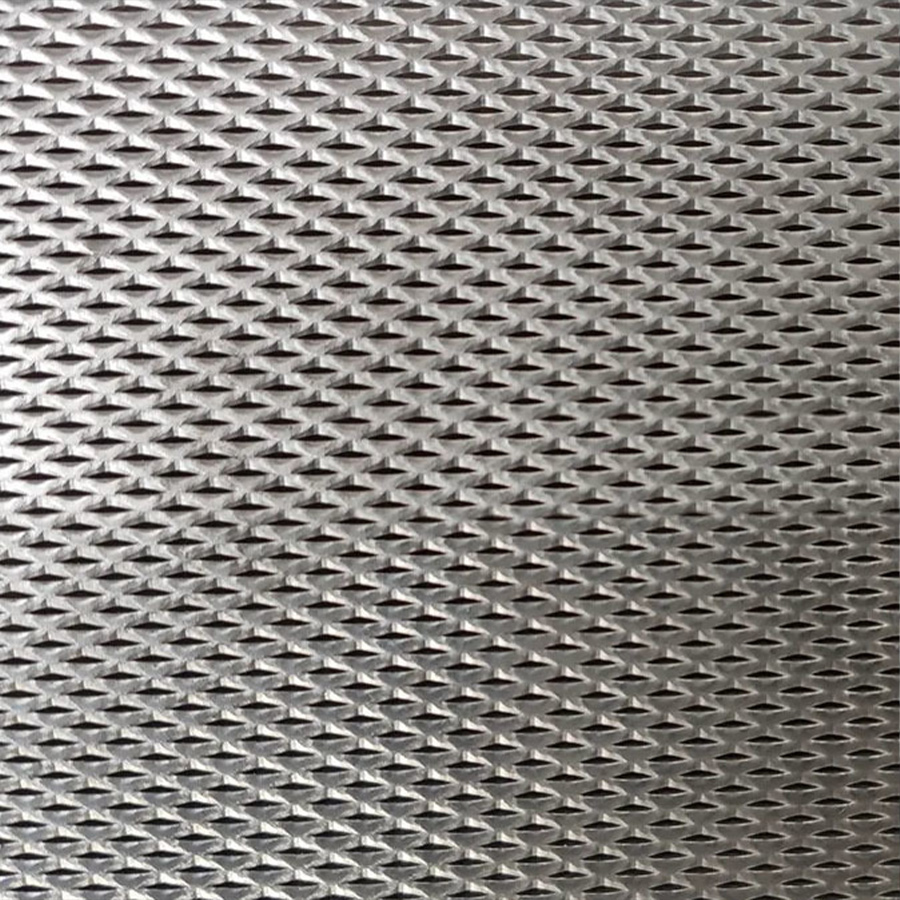

Welded mesh

Welded mesh, commonly used in construction and fencing, offers several key features. It boasts strength and durability due to its welded intersections, providing structural integrity.

Features

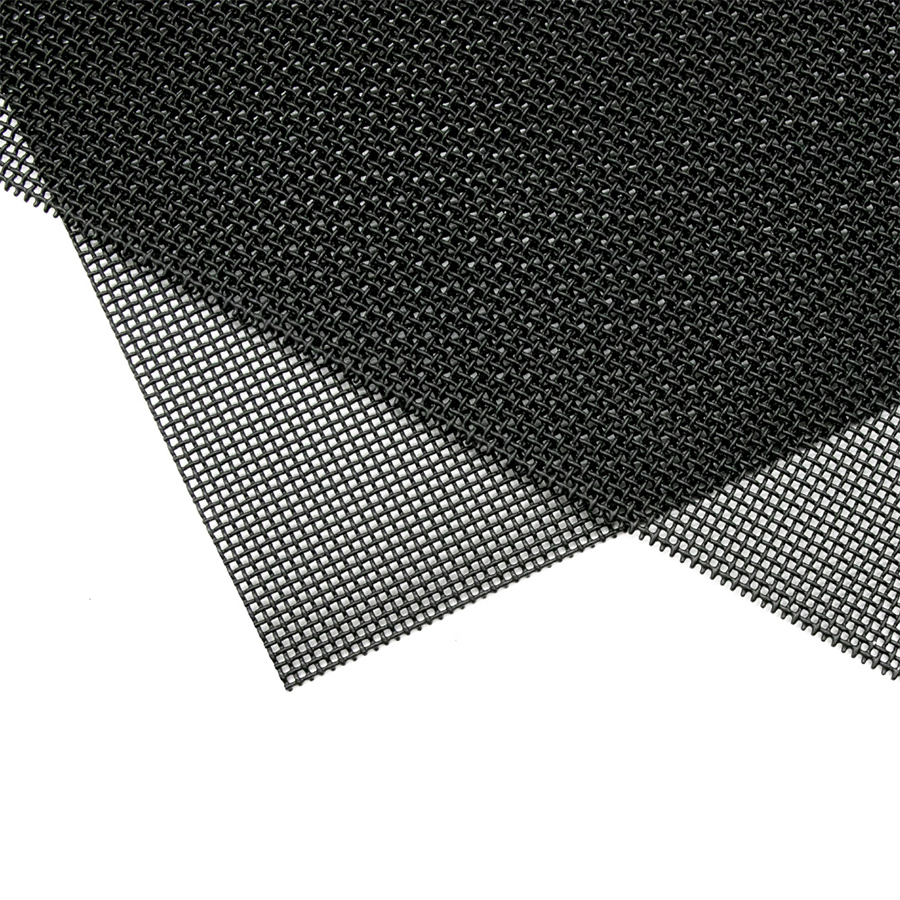

Welded mesh, commonly used in construction and fencing, offers several key features. It boasts strength and durability due to its welded intersections, providing structural integrity. Its uniform grid pattern ensures even distribution of weight and forces. Welded mesh is versatile, suitable for various applications, from reinforcing concrete to creating secure barriers. It's easy to work with, allowing for customization and efficient installation. Moreover, it offers excellent corrosion resistance, making it suitable for outdoor use. These features make welded mesh a reliable choice for a wide range of industrial and residential projects.

Benefits

Welded mesh offers numerous benefits, including enhanced strength and durability due to its welded intersections. Its uniform grid pattern ensures even load distribution. It is versatile, adaptable for various applications such as reinforcement in construction and secure fencing. Welded mesh is easy to work with, allowing for customization and efficient installation. Additionally, it boasts excellent corrosion resistance, making it ideal for outdoor use in various weather conditions. Its long lifespan and low maintenance requirements further contribute to its cost-effectiveness. These advantages make welded mesh a preferred choice for a wide range of industrial, commercial, and residential projects.

Advantages

1.Welded mesh offers several advantages across different industries and applications. Firstly, its welded intersections provide exceptional strength and durability, ensuring structural integrity and longevity. The uniform grid pattern of welded mesh evenly distributes loads, making it ideal for reinforcing concrete structures and providing secure fencing.

2.Welded mesh is versatile, allowing for customization to suit specific project requirements, and it is relatively easy to install, saving time and labor costs. Its corrosion resistance makes it suitable for outdoor use, even in harsh environments, which adds to its longevity.

3.Additionally, welded mesh is an eco-friendly option as it can be recycled and reused, reducing waste. It also offers good visibility, making it an excellent choice for security fencing. Overall, the advantages of welded mesh encompass durability, versatility, cost-effectiveness, and environmental sustainability, making it a popular choice in construction, agriculture, and various other industries.

Spec-Material

Welded mesh is typically made from various materials, including:

1、Steel: This is the most common material for welded mesh. It can be further categorized into:

- Mild Steel: Used for general applications.

- Stainless Steel: Offers excellent corrosion resistance, suitable for outdoor and marine environments.

- Galvanized Steel: Coated with a layer of zinc for added corrosion protection.

2、Aluminum: Lightweight and corrosion-resistant, making it suitable for decorative and lightweight fencing.

3、Copper: Less common but chosen for its unique aesthetic properties and corrosion resistance.

4、Brass: Known for its durability and corrosion resistance, often used in decorative applications.

The choice of material depends on the specific requirements of the project, including factors like strength, corrosion resistance, cost, and aesthetics.

Spec-Chart or Graphic

|

Description |

Welded Wire Mesh |

|

Material |

Low Carbon steel Wire, Galvanized steel wire,Stainless Steel Wire,Aluminum wire,Copper wire,Brass wire |

|

Wire Diameter |

0.2-15mm |

|

Mesh size |

0.5-1.8m or Customized |

|

Hole Size |

1/4",3/8”,1/2",1"1.5",2",3",4"or Customized |

|

Finish

|

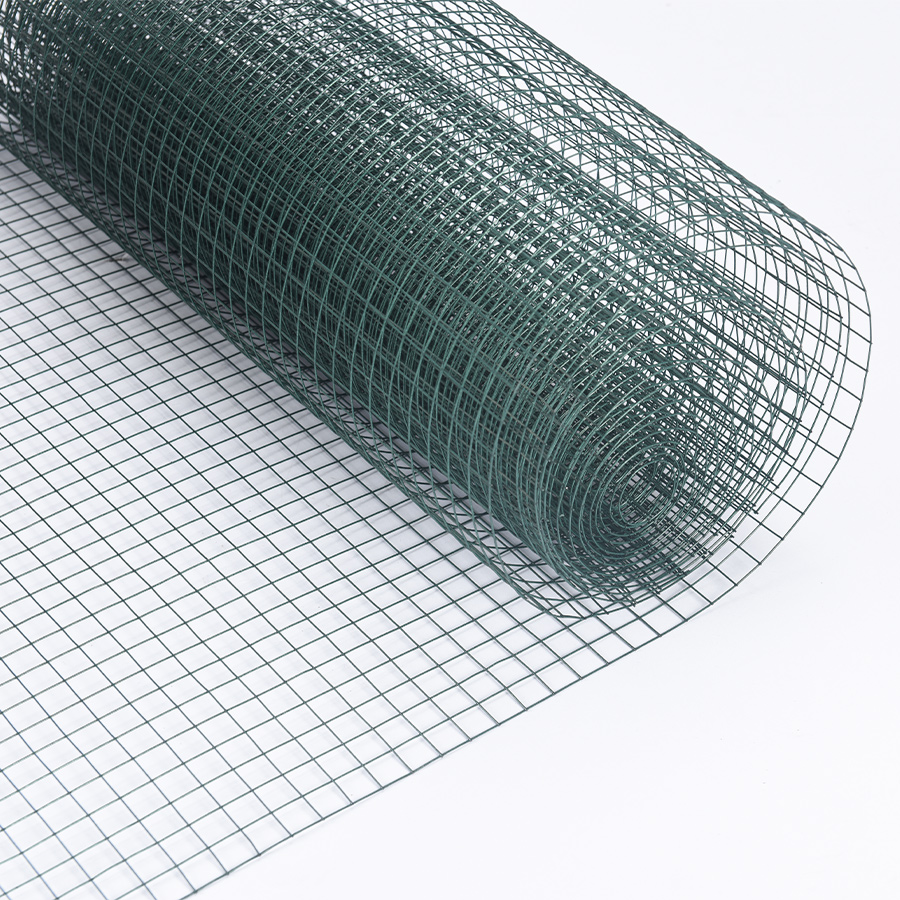

1)Electro Galvanized 2) Hot dipped Galvanized 3) PVC Coated |

|

Color |

1) Dark green 2) Light green 3)Blue 4) Yellow Color 5) White 6) Black 7)Orange 8) Red |

|

Package |

1) In pallet with waterproof cloth 2) In roll with waterproof paper 3) In carton box 4) In roll with plastic shrink 5) In bulk or In bundle |

Spec-Standards

The standard for welded mesh can vary depending on the application and the region in which it is used. Generally, there are several common standards and specifications for welded mesh, including:

1、ASTM (American Society for Testing and Materials): ASTM has several standards related to welded wire mesh, such as ASTM A185 for steel welded wire reinforcement and ASTM A497 for welded wire fabric.

2、BS (British Standards): In the UK, British Standards like BS 4483 and BS 8666 outline specifications for welded fabric and mesh used in concrete reinforcement.

3、DIN (Deutsches Institut für Normung): DIN standards are used in Germany and other European countries. DIN 488 specifies requirements for welded fabric.

4、JIS (Japanese Industrial Standards): JIS standards may be referenced for welded mesh in Japan and some Asian countries.

5、ISO (International Organization for Standardization): ISO has standards related to wire products, which may be relevant to welded mesh in certain cases.

It's important to check the specific standards and specifications that apply to your project, as they can vary based on factors like the type of material used and the intended application of the welded mesh.

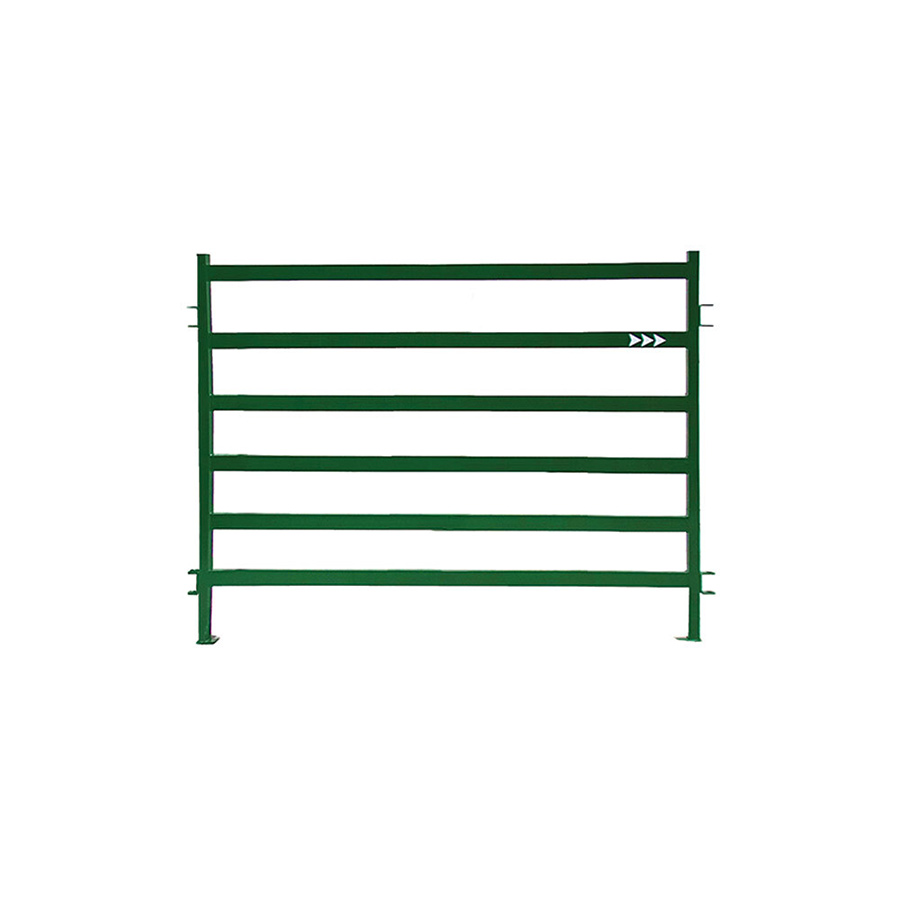

Welded mesh finds a wide range of applications across various industries due to its versatility and durability. Some common applications include:

1、Construction: Used for reinforcing concrete structures, such as roads, bridges, and buildings, to enhance tensile strength and prevent cracking.

2、Fencing: Welded mesh is popular for security fencing around commercial properties, residential homes, and agricultural fields. It offers both security and visibility.

3、Animal Enclosures: Welded mesh is employed to create enclosures for pets, livestock, and zoo animals, ensuring safety and containment.

4、Gardening: Used for trellising, plant support, and fencing in gardens and agriculture to protect plants and provide structural support.

5、Gabion Boxes: Welded mesh is used to construct gabion boxes filled with rocks or stones for erosion control, retaining walls, and landscaping.

6、Mesh Partitions: In industrial settings, welded mesh partitions are used for safety, security, and zoning purposes.

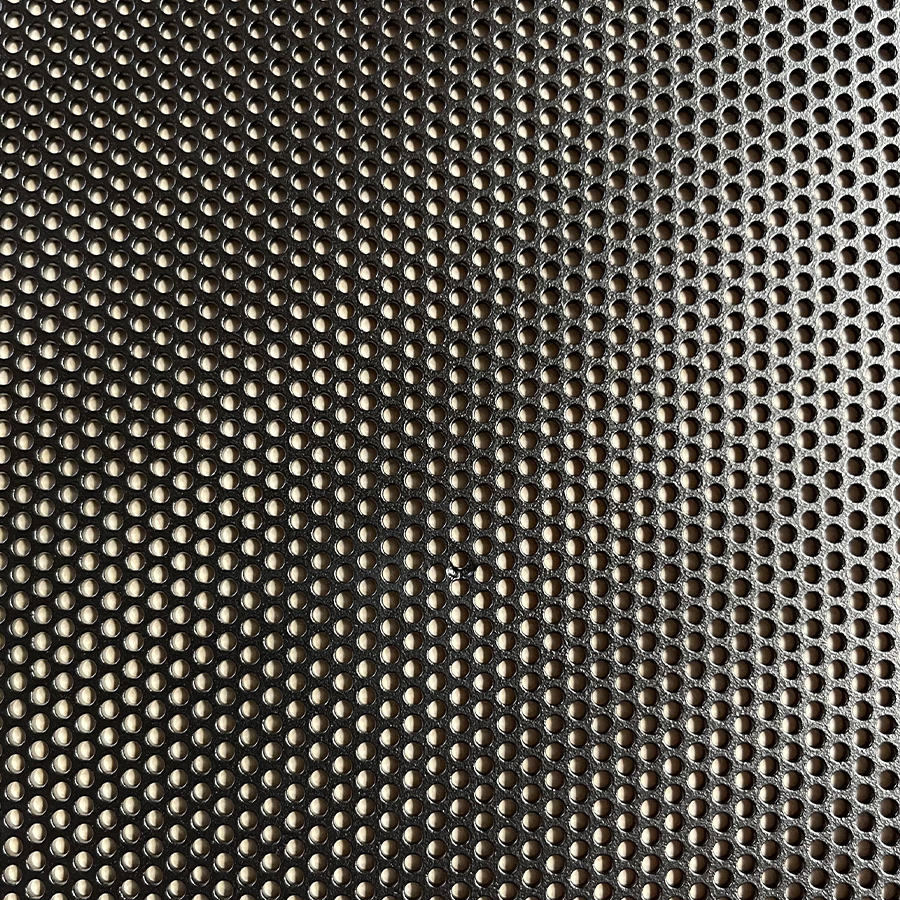

7、Filter Screens: Utilized in industries such as agriculture and aquaculture for filtration and separation of materials.

8、Decorative Applications: Welded mesh is sometimes used in architectural and interior design for decorative elements like screens and dividers.

9、Transportation: Used as safety barriers on roads and highways to prevent accidents.

10、Mesh Baskets and Containers: Employed in material handling, storage, and transportation for their strength and durability.

These are just a few examples of the many applications of welded mesh, showcasing its versatility and utility across various industries and projects.

|

|

The installation of welded mesh typically depends on the specific application and purpose. Here are some general steps for installing welded mesh for a basic fencing application:

Tools and Materials You'll Need:

- Welded mesh panels

- Fence posts

- Concrete mix (for securing posts)

- Nails or clips (for attaching mesh to posts)

- Post hole digger or auger

- Level

- String line

- Hammer

- Saw (if cutting panels)

- Safety gear (gloves, safety glasses, etc.)

Installation Steps:

1、Plan and Mark: Determine the layout and dimensions of your fencing area. Mark the locations for the fence posts at even intervals. Use a string line to ensure a straight line for your fence.

2、Dig Post Holes:Dig holes for the fence posts using a post hole digger or auger. The depth and diameter of the holes should be appropriate for your specific project and local building codes.

3、Set Posts: Place the fence posts in the holes and use a level to ensure they are plumb (vertical). Pour concrete into the holes to secure the posts in place. Allow the concrete to cure according to the manufacturer's instructions.

4、Cut and Attach Panels: If needed, cut the welded mesh panels to fit the desired length and height of the fence. Attach the panels to the posts using nails or clips. Ensure the panels are level and evenly spaced.

5、Secure the Top: Depending on the design, you may need to add a top rail or additional supports to the fence to provide stability and prevent sagging.

6、Finishing Touches:Trim any excess mesh, and inspect the entire fence for stability and security. Make any necessary adjustments or reinforcements.

7、Paint or Finish: If desired, paint or finish the welded mesh fence to protect it from corrosion and enhance its appearance.

8、Gate Installation: If your fence includes a gate, install it according to the manufacturer's instructions, ensuring proper alignment and functionality.

Remember to follow any local building codes and regulations when installing welded mesh fencing, as requirements may vary depending on your location and the specific application.

1、Rolls: Welded mesh is often packaged in rolls, especially for smaller quantities or when the mesh is used for fencing or landscaping. These rolls can vary in width and length to accommodate different project needs.

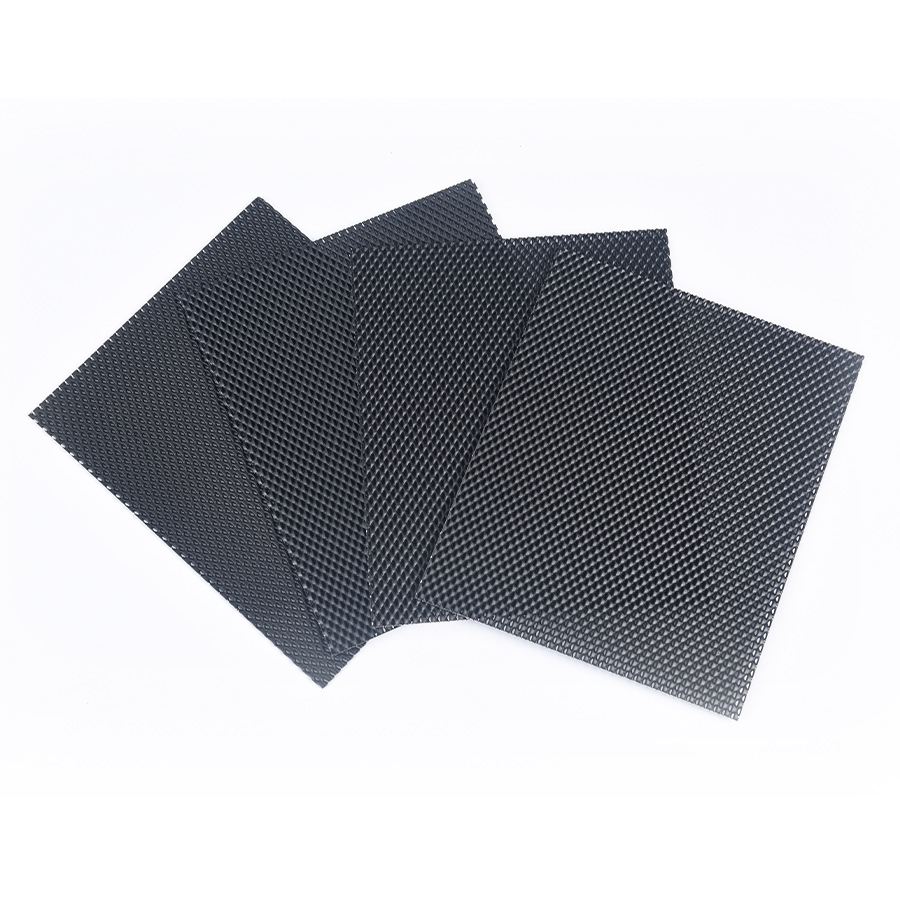

2、Sheets or Panels: For larger quantities or when the mesh is intended for construction or industrial applications, it may be packaged in sheets or panels. These can be stacked and bundled together.

3、Pallets: When ordering large quantities of welded mesh, it is common for the mesh to be stacked and secured on pallets. This method is efficient for storage and transportation.

4、Bundles: Smaller quantities of welded mesh may be bundled together with straps or wire ties for easy handling and transport.

5、Custom Packaging: Depending on the supplier and your specific requirements, you may request custom packaging to meet your project's needs. This could include custom-sized rolls, sheets, or other configurations.

The packaging should protect the welded mesh from damage during transportation and storage, and it should be labeled with important information, such as the mesh specifications, quantity, and handling instructions. Always check the packaging for any damage or discrepancies before accepting a shipment to ensure you receive the correct product in good condition.

|

|