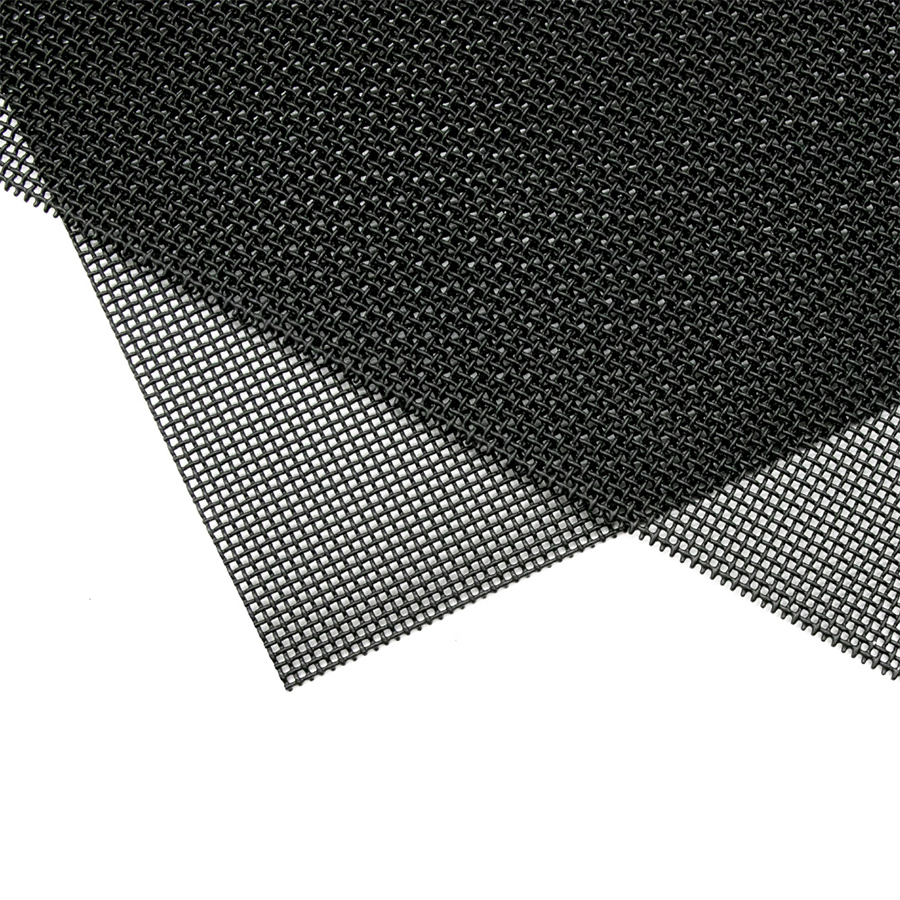

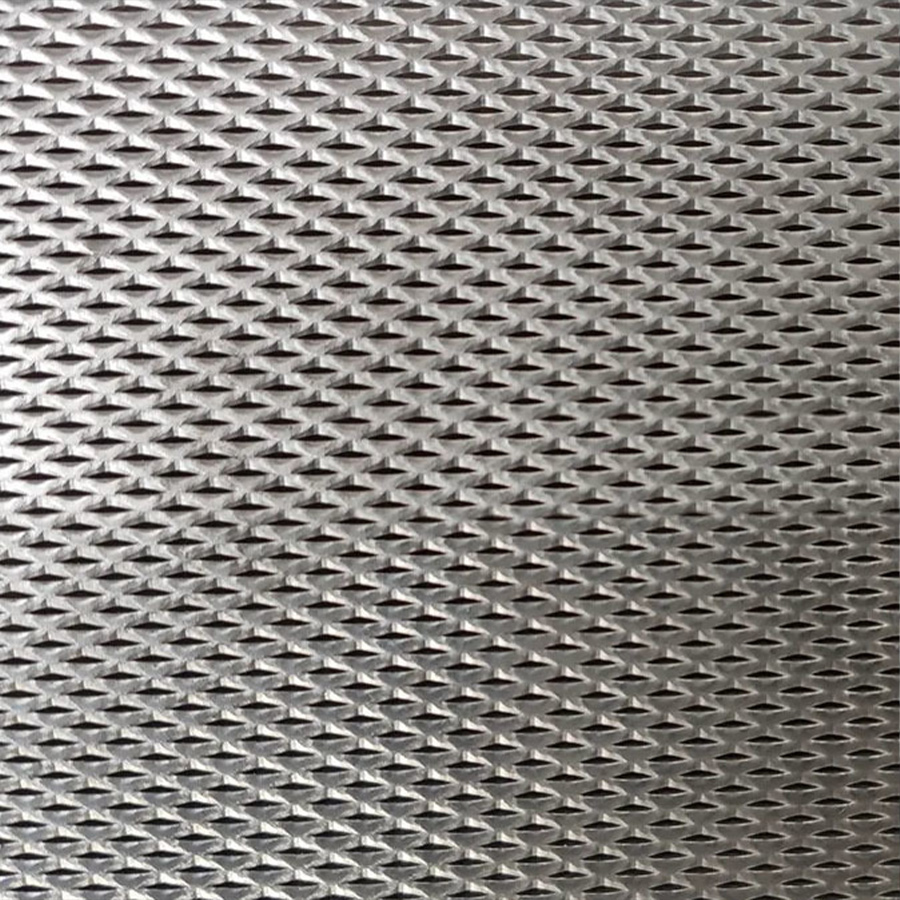

Welded mesh panel

Welded mesh panels boast durability, versatility, and strength. Constructed from welded steel wires, they offer corrosion resistance and adaptability to various environments.

Features

Welded mesh panels boast durability, versatility, and strength. Constructed from welded steel wires, they offer corrosion resistance and adaptability to various environments. These panels are highly flexible, ideal for applications like fencing, construction, and agriculture. Uniform openings ensure consistent airflow and visibility. Easy installation and maintenance make them cost-effective for projects.

Benefits

The benefits of welded mesh panels include:

1、Durability: Welded construction ensures long-lasting performance.

2、Security: Effective for fencing and barrier applications.

3、Versatility: Suitable for various industries and projects.

4、Corrosion Resistance: Maintains integrity in diverse environments.

5、Easy Installation: Simplifies setup, reducing labor costs.

6、Visibility: Provides transparency while offering protection.

7、Cost-Effective: Offers value due to low maintenance and longevity.

8、Customization: Available in various sizes and configurations.

9、Safety: Enhances safety in construction and agriculture.

10、Environmentally Friendly: Recyclable and eco-conscious choice.

Advantages

The advantages of welded mesh panels include:

1、Strength and Durability: Welded construction ensures robustness and longevity.

2、Security: Effective for fencing and security applications.

3、Versatility: Suitable for a wide range of industrial and commercial uses.

4、Corrosion Resistance: Maintains structural integrity in different environments.

5、Easy Installation: Simplifies setup, reducing labor costs.

6、Visibility: Provides visibility while ensuring protection.

7、Customization: Available in various sizes and configurations.

8、Cost-Effective: Offers value due to low maintenance and extended service life.

9、Safety: Enhances safety in construction, agriculture, and other sectors.

10、Sustainability: Recyclable and eco-friendly choice for sustainable projects.

Spec-Material

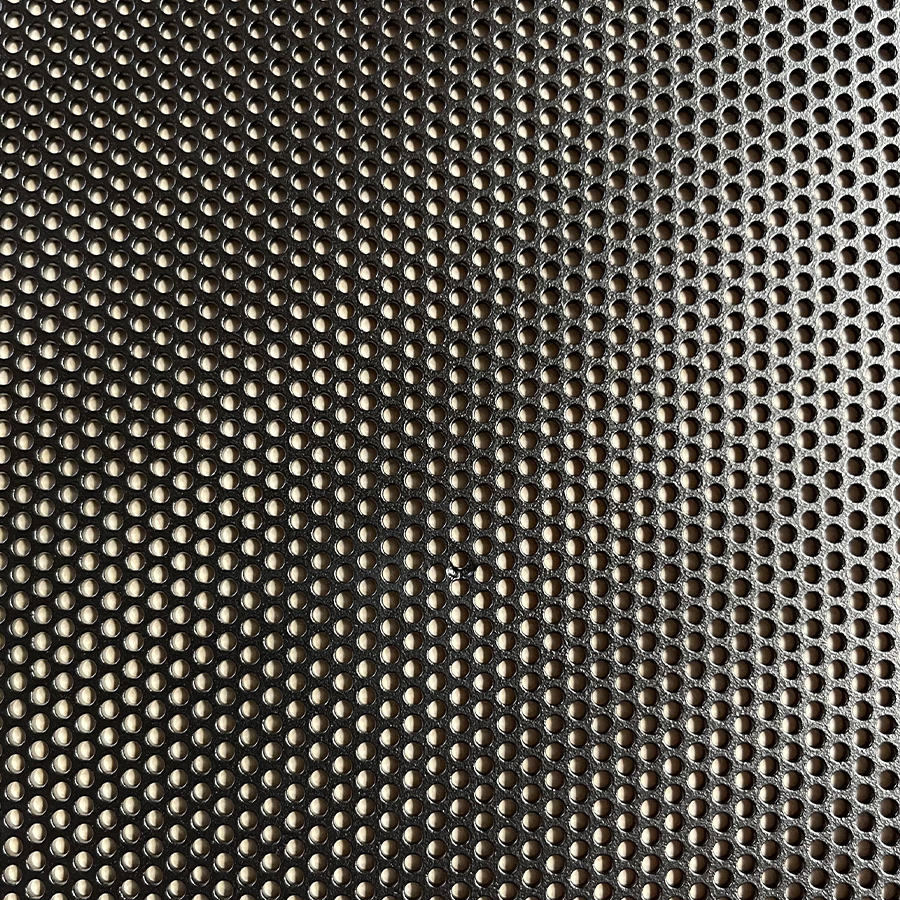

Welded mesh panels are typically fabricated from various materials, including:

1、Steel: The most common choice, available in carbon steel, stainless steel, or galvanized steel for enhanced corrosion resistance.

2、Aluminum: Provides a lightweight option with good corrosion resistance, ideal for decorative or less demanding applications.

3、Galvanized Wire: Steel wire coated with zinc to prevent rust and corrosion.

4、Vinyl-Coated Wire: Steel wire coated with vinyl for added protection and aesthetics.

5、Copper: Rarely used but offers excellent corrosion resistance for specific applications.

6、PVC (Polyvinyl Chloride): Used for coating steel wires, enhancing corrosion resistance and appearance.

Spec-Chart or Graphic

|

Opening size (inch) |

Opening size (mm) |

Wire diameter (Gauge) |

Wire diameter (mm) |

Panel length (m) |

Panel width (m) |

|

1"x1" |

25x25mm |

14-11 Gauge |

2-3mm |

1-6m |

0.5-2.2m |

|

2"x1" |

50x25mm |

14-8 Gauge |

2-4mm |

||

|

2"x2" |

50x50mm |

14-8 Gauge |

2-4mm |

||

|

3"x2" |

75x50mm |

14-6 Gauge |

2-5mm |

||

|

3"x3" |

75x75mm |

14-6 Gauge |

2-5mm |

||

|

4"x2" |

100x50mm |

14-4 Gauge |

2-6mm |

||

|

4"x4" |

100x100mm |

14-4 Gauge |

2-6mm |

||

|

5"x5" |

125x125mm |

14-4 Gauge |

2-6mm |

||

|

6"x6" |

150x150mm |

14-4 Gauge |

2-6mm |

Spec-Standards

Standards for welded mesh panels vary by region and application. However, some commonly referenced standards include:

1、ASTM A185: Standard specification for welded steel wire fabric for concrete reinforcement.

2、ASTM A496: Standard specification for deformed wire for concrete reinforcement.

3、DIN 488: German standard for welded steel wire mesh for concrete reinforcement.

4、BS 4483: British standard for steel fabric for the reinforcement of concrete.

5、EN 1992-1-1: European standard for the design of concrete structures, which includes guidance on welded mesh panels.

6、AS/NZS 4671: Australian and New Zealand standard for steel reinforcing materials, including welded mesh.

It's important to consult the specific standards applicable to your region and project to ensure compliance and quality.

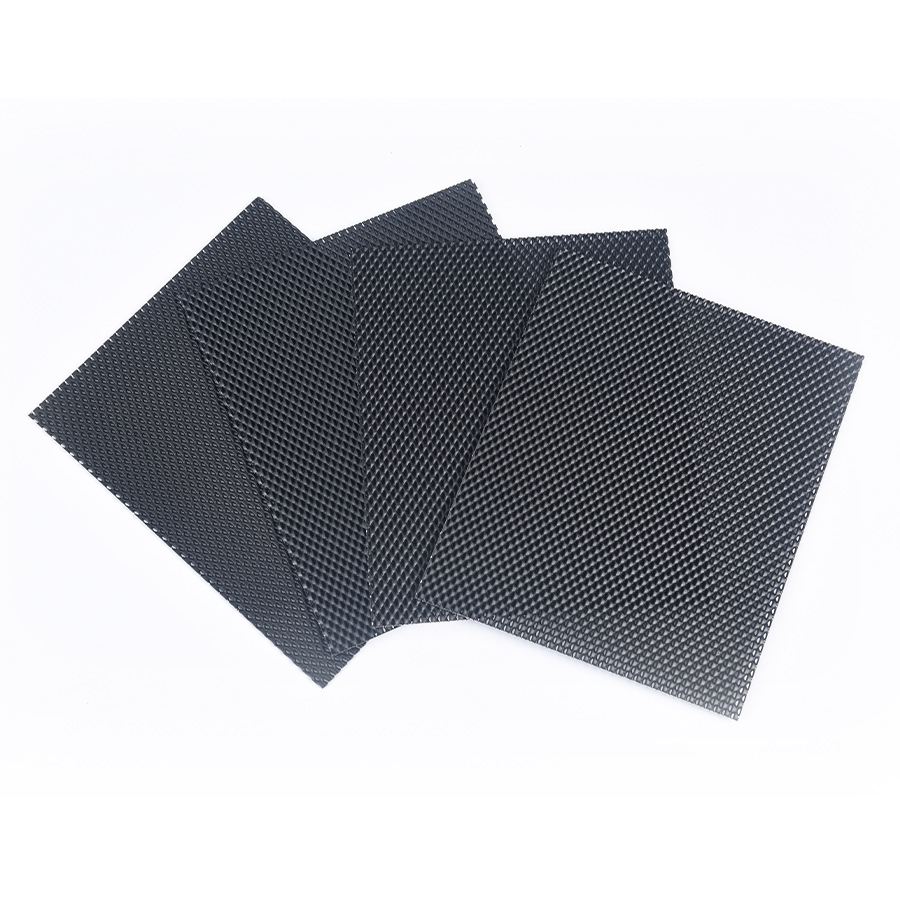

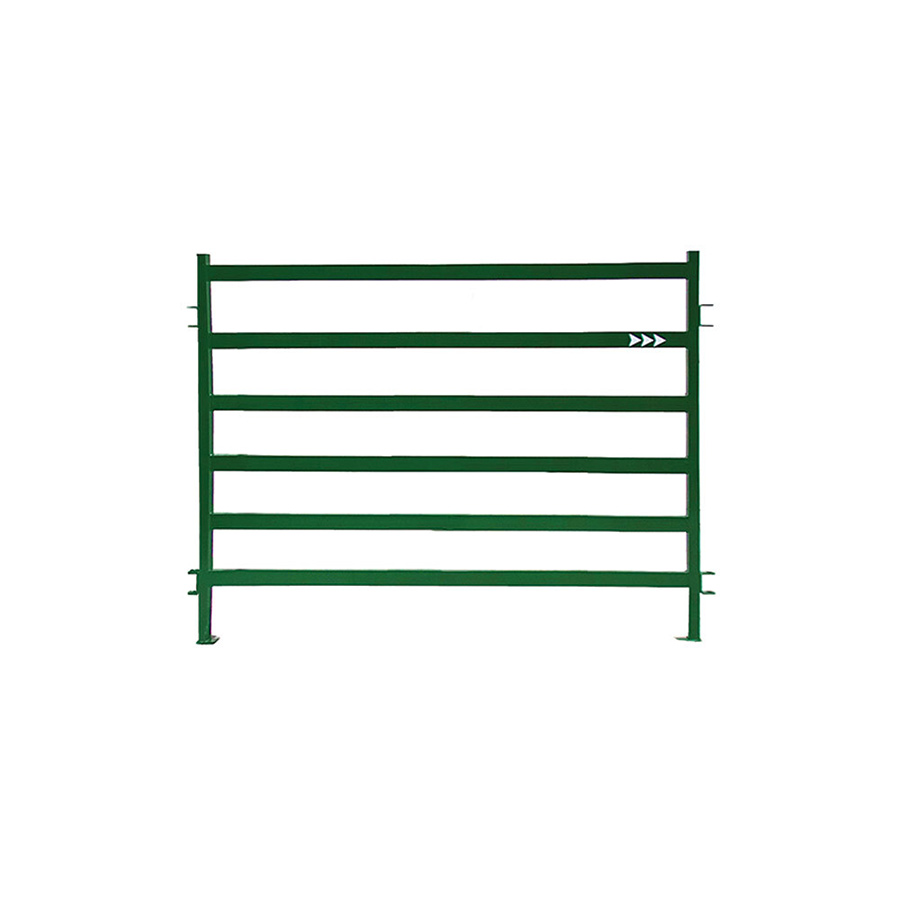

Welded mesh panels find diverse applications across various industries, including:

1、Fencing: Used for perimeter security in residential, commercial, and industrial settings.

2、Construction: Reinforcing concrete structures to enhance strength and durability.

3、Agriculture: Creating enclosures for livestock, poultry, and crop protection.

4、Landscaping: Building trellises, garden fencing, and decorative features.

5、Transportation: Supporting infrastructure like road and bridge construction.

6、Mining: Safety barriers, mesh screens, and ground stabilization.

7、Manufacturing: Partitions, machine guards, and storage racks.

8、Security: Window and door grilles, access control, and anti-climbing barriers.

9、Aquaculture: Cages for fish farming and aquaponics systems.

10、Gabion Boxes: Used in erosion control, retaining walls, and landscaping.

These panels offer versatility and durability, making them valuable in a wide range of applications.

|

|

The installation of welded mesh panels typically involves the following steps:

1、Planning: Determine the panel dimensions, spacing, and layout according to the project requirements.

2、Frame Preparation: If needed, create a sturdy frame or support structure for the mesh panels.

3、Alignment: Ensure proper alignment and level placement of the panels using tools like spirit levels.

4、Fastening: Secure the mesh panels to the frame or support structure using suitable fasteners such as screws, bolts, or clips.

5、Cutting: Trim or cut panels to fit corners, edges, or irregular shapes as necessary.

6、Overlap and Seam Welding: Overlap adjacent panels by a recommended amount and, if applicable, weld seams for added strength and security.

7、Finishing: Apply any necessary coatings, like paint or anti-corrosion treatments, to enhance longevity.

8、Inspection: Thoroughly inspect the installation for proper alignment, structural integrity, and security.

9、Maintenance: Implement regular maintenance to ensure the panels remain in good condition over time.

It's essential to follow specific installation guidelines provided by manufacturers and adhere to safety protocols throughout the process.

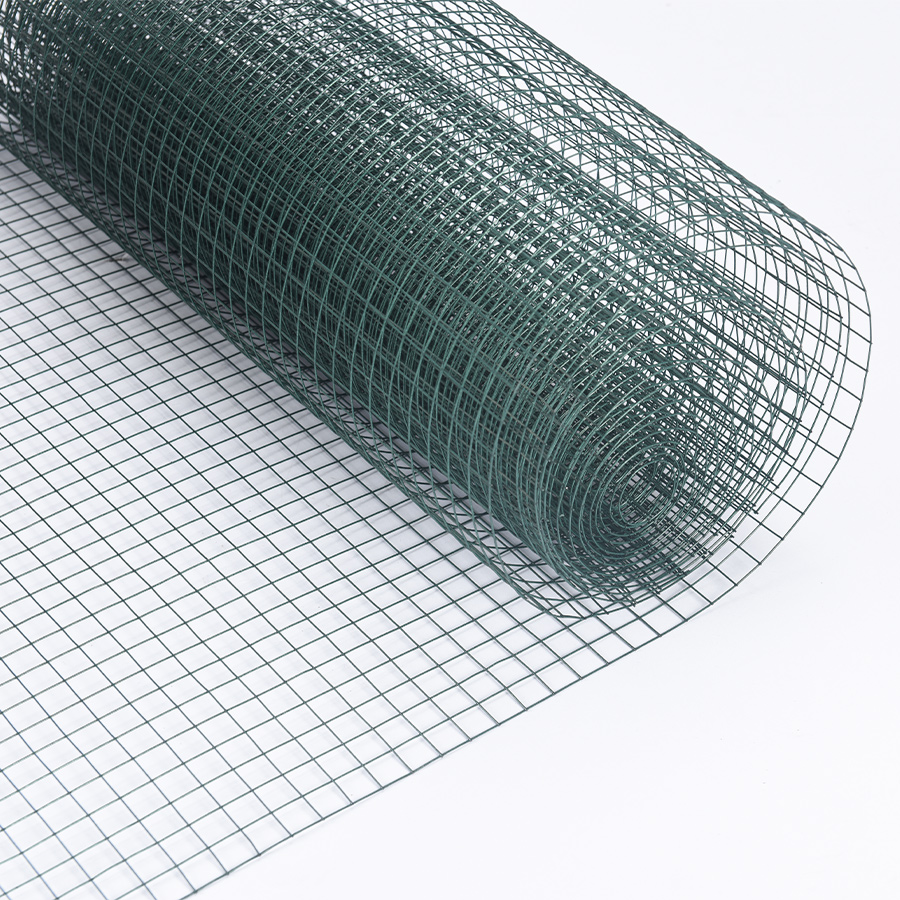

The packaging for welded mesh panels typically involves the following:

1、Bundling: Panels are bundled together using metal straps or wires to prevent individual pieces from shifting during transit.

2、Protective Covering: They may be wrapped in a protective material, such as plastic or paper, to shield against dust, moisture, and potential damage.

3、Palletization: For larger quantities, panels are often stacked on wooden pallets and securely fastened to prevent shifting or tipping.

4、Labeling: Each package is labeled with essential information, including product specifications, quantity, and handling instructions.

The packaging method can vary depending on the manufacturer and the specific requirements of the customer or project. It's essential to inspect packages upon delivery to ensure they are intact and meet your expectations.